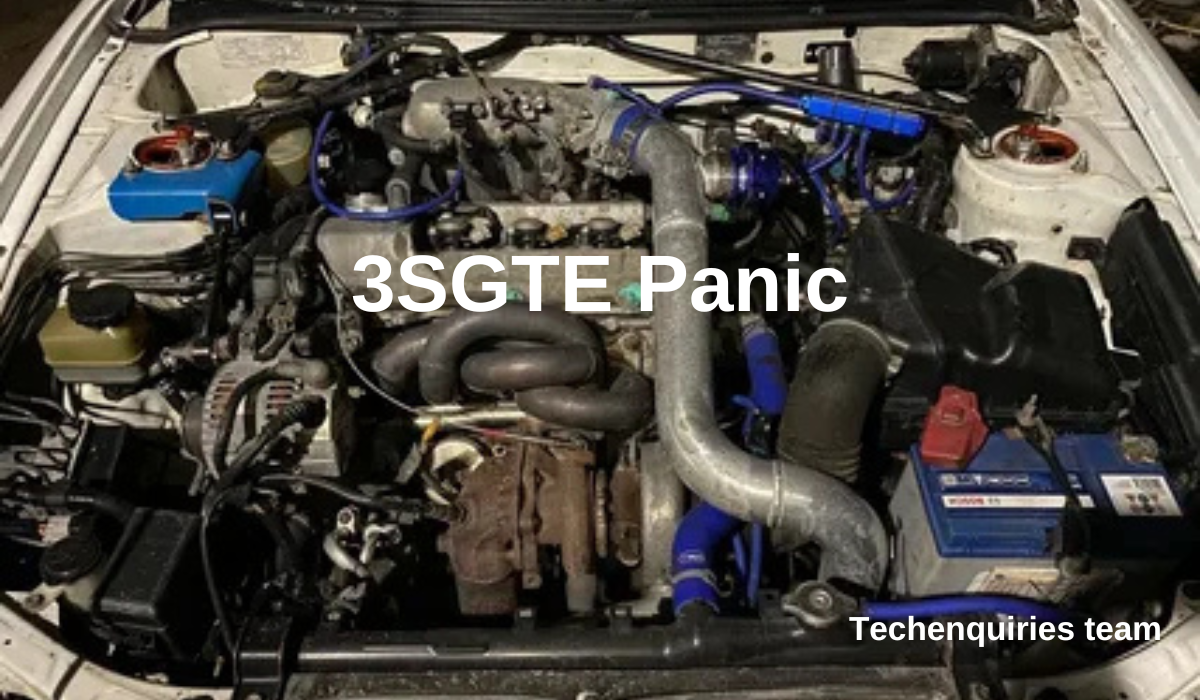

The Toyota 3S-GTE engine, known for its remarkable power, durability, and potential for tuning, has earned its place in the hearts of performance car enthusiasts. Widely used in models like the Toyota Celica GT-Four and Toyota MR2 Turbo, the 3S-GTE has made a lasting impact in motorsports. However, despite its strengths, the 3S-GTE engine can experience issues that lead to moments of anxiety and frustration, often referred to as “3SGTE panic.” Whether it’s a performance hiccup or a serious malfunction, this article will delve deeper into the common causes of 3SGTE panic, how to identify them, and the most effective ways to solve these problems for optimal performance.

What is “3SGTE Panic”?

The term “3SGTE panic” refers to the stress and worry owners feel when their 3S-GTE engine encounters unexpected issues. These problems can range from minor glitches to potentially catastrophic failures, especially in cases where aftermarket modifications or tuning are involved. The 3S-GTE, while robust and capable of handling high-performance demands, can be subject to various problems if not properly maintained or tuned. Knowing what to look for and how to address these issues can prevent unnecessary engine stress and ensure the longevity of your 3S-GTE.

Table of Contents

Common Causes of 3SGTE Panic

The Toyota 3S-GTE engine, while celebrated for its power and performance potential, can sometimes lead to moments of panic for its owners. These moments usually stem from specific engine issues that, if not addressed, could cause serious performance drops or even damage. Understanding the most common causes of 3SGTE panic is key to preventing costly repairs and ensuring the longevity of the engine. Below are some of the main culprits that contribute to 3SGTE panic.

1. Boost-Related Issues

The turbocharger is the heart of the 3S-GTE’s power output, but it is also one of the most sensitive components. Turbocharging issues are common and can lead to drastic drops in performance, or worse, engine damage. The following are some of the key boost-related problems:

- Boost Leaks: Small cracks in intercooler piping, loose clamps, or damaged hoses can cause a significant loss of boost pressure. This results in the engine not receiving enough air, which leads to a noticeable drop in power and efficiency.

- Boost Creep: When the turbo produces more boost than the wastegate is capable of controlling, it results in a condition known as boost creep. If left unchecked, this can lead to overboost, which stresses engine components and can cause serious damage.

- Faulty Wastegate or Blow-Off Valve: A malfunctioning wastegate or blow-off valve can cause erratic boost levels or delayed turbo spool, which affects the throttle response and overall engine performance.

2. Fuel Delivery Problems

Proper fuel delivery is essential to the 3S-GTE’s operation. Issues within the fuel system can disrupt the air-fuel mixture, leading to rough idling, misfires, and engine stalling. Common fuel delivery problems include:

- Failing Fuel Pump: Over time, the stock fuel pump may not be able to supply the necessary fuel volume for a modified or tuned engine, causing fuel starvation. This can lead to a loss of power or even engine stalling under load.

- Clogged or Dirty Fuel Injectors: Dirty fuel injectors can disrupt the fuel flow to the engine, resulting in poor combustion, misfires, or rough idle. This is especially a concern for owners who frequently use lower-quality fuel or neglect regular injector cleaning.

- Fuel Pressure Regulator Failure: A faulty fuel pressure regulator can lead to an imbalanced air-fuel mixture. This can cause the engine to run too rich or lean, affecting performance and fuel economy.

3. Ignition System Failures

The ignition system is responsible for igniting the air-fuel mixture within the engine’s cylinders. Any malfunction here can lead to significant issues such as misfires, engine hesitation, or even failure to start. Common ignition-related problems include:

- Worn Spark Plugs: Over time, spark plugs degrade, and worn plugs may not provide a consistent spark. This can lead to poor acceleration, rough idling, and increased fuel consumption.

- Faulty Ignition Coils: Ignition coils provide the necessary voltage to the spark plugs. If these coils fail or weaken, it can result in misfires, particularly under heavy load or high RPM conditions.

- ECU or Timing Problems: If the engine control unit (ECU) experiences faults or incorrect programming, it can cause improper ignition timing. This could lead to engine knocking, a decrease in power, and reduced fuel efficiency.

4. Cooling System Failures

Because the 3S-GTE is a turbocharged engine, heat management is crucial. Any failure in the cooling system can lead to the engine overheating, causing significant damage. The most common cooling system problems include:

- Leaking or Blocked Radiators: A radiator that is either clogged or leaking will not be able to dissipate heat effectively, leading to increased engine temperatures and potential overheating.

- Worn or Broken Water Pumps: If the water pump fails, coolant circulation is reduced, and the engine can overheat. In the 3S-GTE, this is a major concern, especially when the engine is under heavy load during high-performance driving.

- Insufficient Cooling Capacity: When the engine is modified for increased power, the stock cooling system may struggle to manage the additional heat. Upgrading to a larger radiator, oil cooler, or intercooler may be necessary for high-performance setups.

5. Oil-Related Issues

Lubrication is vital for ensuring the engine components run smoothly and efficiently, especially in a turbocharged setup. Oil-related issues are a significant cause of 3SGTE panic, as they can result in turbo failure, engine wear, and other severe problems.

- Oil Starvation to the Turbo: The 3S-GTE turbo is highly sensitive to oil flow. A lack of sufficient lubrication can lead to premature turbocharger failure, resulting in a complete loss of turbo boost.

- Oil Leaks: Over time, seals, gaskets, or oil lines can wear out, leading to leaks that result in low oil levels. Low oil can cause engine damage and increase wear, particularly on the turbo and other high-stress components.

- Dirty or Incorrect Oil: Using the wrong type of oil or failing to replace the oil at regular intervals can cause sludge buildup or increased friction, which reduces engine efficiency and causes premature wear.

6. Aftermarket Modifications and Tuning Issues

Many 3S-GTE owners choose to modify their engines for enhanced performance. However, improper modifications or tuning can lead to new problems that contribute to 3SGTE panic. Some common issues include:

- Improper Tuning: Aftermarket modifications often require a proper tune to ensure the engine is running efficiently. If tuning is done incorrectly—such as running too rich or too lean—the engine may experience detonation, poor performance, or even catastrophic failure.

- Sensor Mismatches: When aftermarket parts are installed, such as a bigger turbo or injectors, the stock sensors may no longer provide accurate readings. Mismatched sensors can cause the ECU to miscalculate parameters like air-fuel ratios, leading to erratic engine performance.

- ECU Malfunctions: Aftermarket or piggyback ECUs need to be carefully integrated into the vehicle’s system. If the integration is done poorly, it can result in engine issues such as improper fuel mapping, turbo mismanagement, or incorrect timing.

Recognizing Symptoms of 3SGTE Panic

When you own a Toyota 3S-GTE engine, one of the most important skills to have is the ability to recognize the symptoms of potential engine problems early. The 3S-GTE, known for its turbocharged performance and tuning capabilities, can experience a variety of issues that could lead to panic moments if not addressed promptly. Early detection and diagnosis of these symptoms can help prevent major damage and expensive repairs.

Below, we’ll cover the most common symptoms of 3SGTE panic, providing insight into what might be going wrong and how to address it before it becomes a major issue.

1. Check Engine Light (CEL) Illuminates

One of the first signs that something may be wrong with your 3S-GTE engine is the illumination of the Check Engine Light (CEL). This light can indicate a wide range of issues, from minor problems to severe mechanical failures. Some of the potential causes include:

- Faulty Sensors: A malfunctioning sensor, such as the oxygen or knock sensor, could trigger the CEL.

- Fuel Delivery Problems: Issues with the fuel injectors or fuel pump could cause a lean or rich fuel mixture, triggering the light.

- Ignition Issues: Faulty spark plugs, ignition coils, or even ECU malfunctions can cause the CEL to come on.

It’s essential to use an OBD-II scanner to read the fault codes and determine the root cause of the issue.

2. Loss of Power and Sluggish Performance

If you notice that your 3S-GTE engine feels sluggish or unresponsive, it could be a sign of underlying issues. Power loss may manifest as:

- Turbocharger Problems: If the turbocharger is failing or if there are boost leaks, the engine may struggle to reach the desired power levels. Loss of boost pressure or inconsistent turbo performance can result in a significant power drop.

- Fuel System Issues: A clogged fuel injector, failing fuel pump, or blocked fuel filter can restrict fuel flow, leading to inadequate combustion and a noticeable drop in engine power.

- Ignition System Failures: If the spark plugs, ignition coils, or timing are off, you may experience engine misfires, which will reduce power, especially under load.

3. Excessive Smoke from the Exhaust

Excessive smoke coming from the exhaust can indicate a range of problems. The color of the smoke can help pinpoint the issue:

- Blue Smoke: This typically indicates that the engine is burning oil. Possible causes include worn piston rings, valve seals, or a failing turbocharger. If the turbo seals are worn, it can allow oil to enter the intake or exhaust system, burning and causing blue smoke.

- White Smoke: White smoke is usually a sign of coolant entering the combustion chamber. This could be a result of a blown head gasket, cracked engine block, or leaking cylinder head. If this is the case, the engine may overheat, and you may need to address coolant leaks immediately.

- Black Smoke: Black smoke is typically a sign that the engine is burning too much fuel, meaning the air-fuel mixture is too rich. This can be caused by issues such as a malfunctioning mass airflow sensor, a faulty fuel pressure regulator, or improper tuning.

4. Unusual Engine Noises

Unusual sounds coming from the engine can often be the most alarming symptom of 3SGTE panic. These sounds could indicate a serious problem that needs immediate attention:

- Whistling or Hissing Noises: These sounds could indicate a boost leak. If you hear a hissing noise when you accelerate, it’s worth checking for leaks in the intercooler piping, vacuum lines, or other parts of the intake system.

- Knocking or Pinging: If you hear a knocking or pinging noise under load, it’s often a sign of detonation or pre-ignition, which can be caused by improper tuning, low-quality fuel, or incorrect ignition timing. Detonation can cause severe engine damage, so it’s crucial to address it immediately.

- Grinding or Rattling: If you hear a grinding or rattling noise, it may indicate an issue with the turbocharger, water pump, or timing components. These noises should not be ignored, as they can signal internal component failure.

5. Erratic Idling

An engine that idles unevenly or surges between higher and lower RPMs may indicate an issue that needs to be addressed. Some potential causes of erratic idling include:

- Vacuum Leaks: A vacuum leak in the intake system can cause the engine to idle erratically. This could be due to cracked hoses, loose connections, or damaged intake manifold seals.

- Ignition Issues: If the spark plugs or ignition coils are worn or malfunctioning, the engine may struggle to maintain a stable idle. Misfires can lead to inconsistent RPMs and rough idling.

- ECU or Fuel Management Problems: If the ECU is improperly tuned or the fuel injectors are malfunctioning, it may lead to inconsistent fuel delivery and erratic idling.

6. Overheating

Overheating is one of the most critical symptoms to watch out for in the 3S-GTE engine. High temperatures can lead to permanent damage, including warped cylinder heads, blown gaskets, and even a seized engine. Common causes of overheating include:

- Coolant Leaks: Leaks in the radiator, hoses, or water pump can result in coolant loss, leading to overheating. If you notice a drop in coolant levels, it’s essential to check for leaks right away.

- Clogged Radiator or Cooling System: Over time, radiators can become clogged with debris or rust, which reduces the system’s cooling efficiency. Flushing the cooling system can help prevent this problem.

- Failing Water Pump: The water pump circulates coolant throughout the engine. If it fails, the coolant will not flow properly, resulting in elevated engine temperatures.

- Broken Thermostat: If the thermostat becomes stuck in a closed position, it will prevent coolant from circulating through the engine, causing it to overheat.

7. Fueling Issues and Poor Fuel Economy

If your 3S-GTE is consuming more fuel than usual or having trouble maintaining proper fuel pressure, it could be a sign of fuel system problems:

- Low Fuel Pressure: A weak or failing fuel pump can cause a drop in fuel pressure, which may lead to hesitation, stalling, or poor throttle response.

- Inaccurate Air-Fuel Ratio: Problems with the mass airflow sensor, fuel pressure regulator, or oxygen sensors can cause the engine to run too rich or too lean. This will affect fuel economy and performance.

Preventing 3SGTE Panic: Proactive Maintenance and Smart Modifications

The Toyota 3S-GTE engine is renowned for its performance, reliability, and tuning potential, but like any high-performance engine, it requires care and attention to avoid common issues that can lead to what enthusiasts often refer to as “3SGTE panic.” Whether you’re looking to maintain a stock engine or have heavily modified your setup, taking preventive measures is essential to ensuring that your 3S-GTE continues to deliver the power and reliability you expect.

In this section, we’ll dive into practical steps for preventing 3SGTE panic, covering regular maintenance, quality upgrades, and the importance of tuning to keep your engine in top shape.

1. Performing Regular Maintenance

Routine maintenance is the cornerstone of preventing engine issues and reducing the likelihood of panic moments. By keeping your engine well-maintained, you can catch potential problems early before they escalate. Here are some key maintenance practices for the 3S-GTE engine:

Oil Changes and Lubrication

Oil is the lifeblood of any engine, and the 3S-GTE’s turbocharged design puts extra stress on its components. Regular oil changes are essential for maintaining smooth operation and preventing premature wear.

- Change the oil every 3,000–5,000 miles, depending on driving conditions and the type of oil you use. Always choose high-quality synthetic oil formulated for turbocharged engines to ensure proper lubrication, especially in high-performance scenarios.

- Check oil levels regularly and ensure there are no oil leaks from seals, gaskets, or turbo lines. Low oil levels can lead to turbocharger failure and significant engine damage.

Replace Air and Fuel Filters

Clogged air and fuel filters restrict airflow and fuel delivery, which can cause performance issues. To avoid this:

- Replace the air filter every 12,000–15,000 miles or sooner if you drive in dusty conditions.

- Change the fuel filter periodically (around every 30,000–40,000 miles) to prevent clogging and ensure proper fuel flow to the engine.

Inspect Belts, Hoses, and Seals

Over time, rubber components like belts and hoses can crack, wear, or become brittle, leading to leaks or failures.

- Check all belts and hoses for wear or damage, especially those connected to the turbo system. Replace them as needed to avoid sudden breakdowns.

- Inspect seals and gaskets for oil or coolant leaks. These can lead to major issues such as coolant loss, overheating, and engine misfires.

Coolant System Maintenance

The 3S-GTE engine is prone to heat buildup, especially under hard driving. To prevent overheating and cooling system failure:

- Flush the coolant system every 2 years or 30,000 miles to prevent buildup of debris and rust.

- Check the radiator for blockages or leaks, and replace any damaged components.

- Ensure the thermostat is functioning properly to regulate engine temperature.

2. Upgrading Key Components

As your 3S-GTE engine grows in power, especially after modifications or tuning, upgrading key components is essential for preventing engine failure and improving reliability. Certain aftermarket parts can help enhance the engine’s performance and longevity, but it’s crucial to select quality components.

Upgraded Fuel System

A robust fuel system ensures that the engine receives the proper amount of fuel under various conditions.

- Install a high-flow fuel pump if you’re increasing power, as the stock pump may not be able to handle the extra demand.

- Upgrade the fuel injectors to match your engine’s new power output. Higher-flow injectors will prevent fueling issues that can cause misfires and detonation.

- Check fuel pressure regularly to ensure there are no irregularities in fuel delivery that could lead to engine misfires or lean conditions.

Improved Turbocharger and Intercooler

The turbocharger is the heart of the 3S-GTE engine’s performance, but it can also be a source of problems if not maintained or upgraded properly.

- Upgrade the turbocharger if you’re pushing more horsepower than the stock turbo can handle. A larger turbo or a ball-bearing turbo can provide better spool times and more consistent boost.

- Upgrade the intercooler to improve the cooling efficiency of the intake air. A larger or more efficient intercooler can help prevent heat soak, improving power and reducing the risk of detonation.

- Replace any worn turbo seals to prevent oil or coolant leaks, which can lead to costly repairs if not addressed early.

Improved Cooling System

Turbocharged engines like the 3S-GTE generate a lot of heat, and inadequate cooling can lead to overheating and engine damage.

- Install a larger, more efficient radiator to improve cooling capacity. The factory radiator may not be sufficient for higher power builds or aggressive driving.

- Upgrade the oil cooler to keep the oil temperature under control, especially if you’re running a high-performance build.

- Ensure the water pump is functioning properly to circulate coolant through the engine and prevent overheating.

3. Proper Tuning and ECU Management

When it comes to high-performance engines, proper tuning is crucial to prevent performance issues and engine damage. A well-tuned engine runs efficiently, reduces the risk of detonation, and ensures all components are working harmoniously. Here are some tuning-related steps to avoid 3SGTE panic:

Use a Professional Tuner

The 3S-GTE is highly sensitive to tuning, especially if you have aftermarket modifications. A professional tuner who understands the 3S-GTE platform can help you achieve a balanced air-fuel ratio, boost levels, and ignition timing.

- Work with a tuner experienced with the 3S-GTE engine. They will know how to fine-tune the fuel maps and boost settings to ensure smooth operation and optimal performance.

- Consider using a standalone ECU for greater control over your engine’s parameters, including fuel, boost, and ignition timing. This provides better accuracy and flexibility compared to the stock ECU.

Monitor Critical Parameters

Modern tuners often use data logging tools to monitor engine health and performance in real time. By tracking parameters like air-fuel ratio (AFR), boost levels, and coolant temperature, you can spot issues before they escalate.

- Install gauges for key parameters such as boost pressure, oil pressure, and AFRs to stay informed about your engine’s health.

- Use a data-logging system to monitor engine performance over time. This allows you to diagnose problems early and make adjustments before damage occurs.

Regularly Check for Codes and Errors

Even with a well-tuned engine, things can go wrong. Regularly scanning for error codes or using a wideband oxygen sensor can provide insight into the engine’s performance.

- Scan the ECU for error codes periodically to identify potential issues that may be lurking under the surface.

- Use a wideband O2 sensor to keep an eye on your air-fuel ratios. Lean or rich conditions can lead to engine damage, so ensuring the proper AFR is crucial.

4. Avoiding Overmodification

While it’s tempting to make extensive modifications to the 3S-GTE to increase performance, it’s important to avoid overmodifying the engine beyond its capabilities. Modifications such as excessive boost or extreme tuning can put unnecessary strain on the engine and turbo system, leading to reliability issues.

- Avoid pushing the engine beyond its safe limits. If you plan on adding more power, make sure all related components (fuel, cooling, and exhaust) are upgraded accordingly.

- Focus on balanced modifications that enhance performance without compromising reliability. Ensure that your turbo, fuel, and exhaust systems are appropriately matched for your desired power output.

Diagnosing and Resolving 3SGTE Issues: A Step-by-Step Guide

The Toyota 3S-GTE engine is known for its reliability and performance, but even the most robust engines can experience issues, particularly when subjected to high-performance driving or modifications. Proper diagnosis and timely resolution are crucial to maintaining the engine’s longevity and performance. In this section, we will walk through common 3SGTE problems, how to diagnose them, and the most effective methods for resolving each issue.

1. Boost Leaks and Turbocharger Issues

Diagnosis:

Boost leaks are one of the most common causes of performance issues in turbocharged engines like the 3S-GTE. When boost leaks occur, the engine loses pressure, leading to poor acceleration, reduced power, and sometimes a rough idle.

- Signs of boost leaks: A noticeable drop in power, a sudden loss of boost, or inconsistent throttle response are all indicators.

- Testing for leaks: Perform a smoke test or a boost leak test using a pressure tester to check the intake piping, intercooler, and turbo connections for leaks. Listen for any hissing sounds around the turbo and intake components.

Resolution:

Once a leak is detected, fixing the issue typically involves:

- Inspecting and replacing damaged hoses: Look for cracks, tears, or weakened hoses in the intake system and replace them.

- Tightening clamps: Loose clamps or couplers can cause leaks. Tighten them securely to prevent pressure loss.

- Sealing the intercooler: If you have an aftermarket intercooler, check for any loose connections or damaged seals that may need resealing or replacing.

- Check turbocharger seals: If you suspect the turbo itself is leaking, inspect the turbo seals. In some cases, a turbo rebuild or replacement may be necessary if there’s significant damage.

2. Fuel Delivery Issues

Diagnosis:

A weak or inconsistent fuel supply can lead to a wide variety of engine issues, from poor performance to misfires. Common fuel system problems include a failing fuel pump, clogged fuel injectors, or a malfunctioning fuel pressure regulator.

- Signs of fuel issues: Symptoms like rough idling, hesitation during acceleration, poor throttle response, or stalling can indicate fuel delivery problems.

- Checking fuel pressure: Use a fuel pressure gauge to test the fuel pressure at the fuel rail. If pressure is too low, it could indicate a failing fuel pump, clogged fuel filter, or bad pressure regulator.

- Inspecting injectors: Remove and inspect the fuel injectors for any clogs or leaks. If injectors are dirty, they can cause uneven fuel delivery, leading to poor performance or misfires.

Resolution:

- Replace the fuel filter: If the fuel filter is clogged, replace it to ensure proper fuel flow.

- Replace or clean fuel injectors: Cleaning injectors with a professional injector cleaning service or replacing them with new ones can resolve fuel delivery problems.

- Replace the fuel pump: If the fuel pump is failing or unable to meet the engine’s demands, replace it with an upgraded unit that can handle higher fuel flow, especially in modified engines.

- Fix fuel pressure regulator: If the regulator is malfunctioning, it should be replaced to restore proper fuel regulation.

3. Ignition System Failures

Diagnosis:

The ignition system is responsible for igniting the air-fuel mixture, and any failure in this system can lead to misfires, rough idling, or loss of power. Key components to check include spark plugs, ignition coils, and the ignition timing.

- Signs of ignition issues: Misfires, poor fuel economy, rough idle, or hesitation under load.

- Inspecting spark plugs: Remove the spark plugs to check for wear or deposits. If they appear fouled or worn out, they need to be replaced.

- Checking ignition coils: A malfunctioning ignition coil can lead to a weak spark or no spark at all. Test the coils for continuity with a multimeter.

Resolution:

- Replace spark plugs: Ensure the correct spark plug type and gap for the 3S-GTE engine. Upgrading to iridium plugs can help with better performance and longevity.

- Replace ignition coils: If any coils are found to be faulty, replace them to restore proper spark.

- Retune the ECU: If the timing is off, the ECU may need to be adjusted to optimize ignition timing. This is especially important for modified engines that require fine-tuned adjustments.

4. Overheating and Cooling System Failures

Diagnosis:

Overheating is a serious issue that can lead to engine damage. Common causes of overheating in the 3S-GTE include a blocked or damaged radiator, a failing water pump, or insufficient coolant levels.

- Signs of overheating: Fluctuating or high temperature readings on the dashboard, smoke from under the hood, or steam coming from the engine bay.

- Checking the cooling system: Inspect the radiator for any visible blockages or damage. Look for coolant leaks around the radiator, hoses, or water pump.

- Testing the water pump: Check for any signs of leaks around the water pump or listen for unusual noises that indicate bearing failure.

Resolution:

- Flush the cooling system: Regularly flushing the radiator and coolant system helps remove debris, scale, and contaminants that can block coolant flow.

- Replace the radiator: If the radiator is cracked or clogged, it may need to be replaced with an upgraded unit for better heat dissipation.

- Replace the water pump: If the water pump is not circulating coolant effectively, it should be replaced to prevent overheating.

- Check coolant levels: Ensure coolant is topped off and free from contaminants.

5. Oil Starvation and Turbo Failure

Diagnosis:

Oil starvation, particularly to the turbocharger, can cause significant engine damage and premature turbo failure. Turbochargers are highly dependent on a constant flow of clean oil for lubrication, and without it, they can seize or wear out quickly.

- Signs of oil issues: Excessive smoke from the exhaust, especially blue smoke (indicating oil burning), or a noticeable decrease in turbo performance.

- Inspecting oil lines: Check the turbo’s oil supply and return lines for leaks, clogs, or kinks that may restrict oil flow.

- Oil pressure testing: Use an oil pressure gauge to test the pressure at idle and under load. Low oil pressure can lead to inadequate lubrication.

Resolution:

- Check for oil leaks: Inspect all oil lines and seals for leaks. Replace any damaged components to prevent oil loss.

- Clean or replace the turbo: If oil starvation has occurred, the turbo may need to be rebuilt or replaced. A professional rebuild will restore the turbo’s performance and longevity.

- Use the correct oil: Ensure that you are using the proper oil grade and that it is changed regularly. High-quality synthetic oils are recommended for turbocharged engines.

6. ECU and Sensor Malfunctions

Diagnosis:

The ECU (Engine Control Unit) is responsible for controlling various aspects of the engine, including fuel delivery, ignition timing, and boost levels. A malfunctioning ECU or sensor can cause poor performance or even engine failure.

- Signs of ECU issues: Erratic idle, poor fuel economy, inconsistent power delivery, or the engine running rich or lean.

- Diagnosing ECU faults: Use an OBD-II scanner to check for any error codes. If the ECU is throwing codes related to fuel, timing, or sensor readings, it may need recalibration or replacement.

- Testing sensors: Check the mass airflow sensor (MAF), throttle position sensor (TPS), and oxygen sensors for proper readings using a multimeter.

Resolution:

- Recalibrate or replace the ECU: If the ECU is malfunctioning or needs a software update, recalibrate it or replace it with a more suitable aftermarket unit.

- Replace faulty sensors: If any sensors are giving inaccurate readings, replace them with new or upgraded versions to restore proper engine performance.

- Check wiring and connections: Ensure that all wiring and connections to the ECU and sensors are secure and free of corrosion.

Conclusion

While owning a Toyota 3S-GTE can be an incredibly rewarding experience, it requires consistent maintenance, attention to detail, and awareness of potential issues. By understanding the common causes of 3SGTE panic and how to address them, you can keep your engine in peak condition and continue to enjoy its exhilarating performance. Through regular maintenance, upgrading critical components, and working with a skilled tuner, you can minimize the chances of experiencing unexpected issues and ensure your 3S-GTE remains a reliable powerhouse on the road or track.

YOU MAY LIKE: Matt is a Jerk 2BFP: Navigating Toxicity in Sensitive Fertility Discussions